Sinter-Plate Filters for Dust Filtration, DELTA² PE Sintering Filter, Pleated Sinter Board

Factory, Suppliers From China

Sintered PE Surface filter technology bases on pure surface filtration. It sustainably protects man and machine from harmful production emissions and enables absolutely sort- and contamination-free material recovery. This increases directly your productivity.

Lowest clean gas values, absolutely constant operating conditions, highest availability and energy efficiency are key features of the innovative technology. Sintered PE Surface filter elements show extreme durability and, depending on the process, long service life times of more than 15 years. Thereby the filters make a valueable contribution to environmental protection and sustainability.

Sintered PE Surface filter elements have proven themselves for decades in effective and safe particle separation in almost all areas of industry . Even with finest grain sizes, energy-efficient air recirculation is possible in most cases, proven even with toxic dust.

Filter element lifetime of up to 15 years possible

Low maintenance costs due to long useful life of the filter elements

Constant pressure drop guarantees consistent air flow

High separation efficiency due to surface filtration

Clean gas emissions <1.0 mg/m3

Compact rigid body generates a robust filter design

Filter medium: capable to be washed, recycled and refurbished

Universal mounting from the raw- or clean gas side of the filter unit

Horizontal or vertical installation possible

Filter medium absolutely free of fibers, ideal for product recovery

Excellent use for highly abrasive dusts

Antistatic version of the filter elements available

FDA-conformity by using food-grade filter material

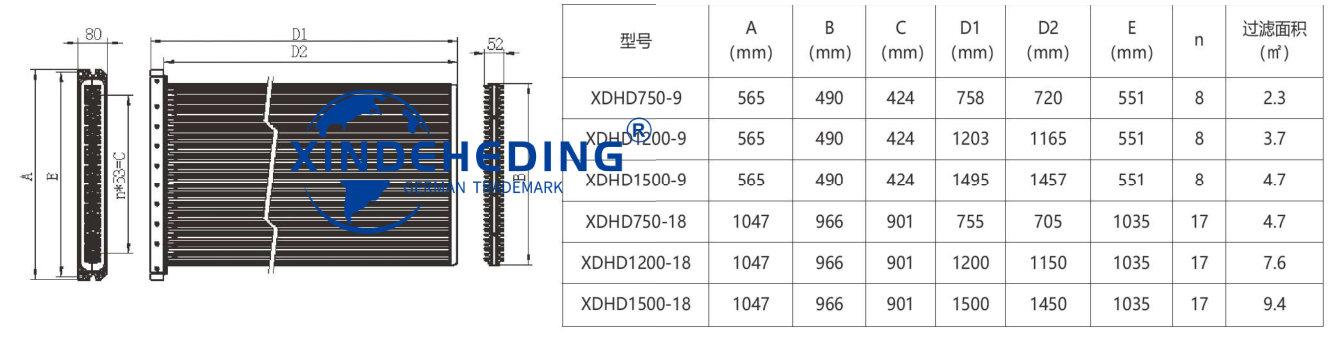

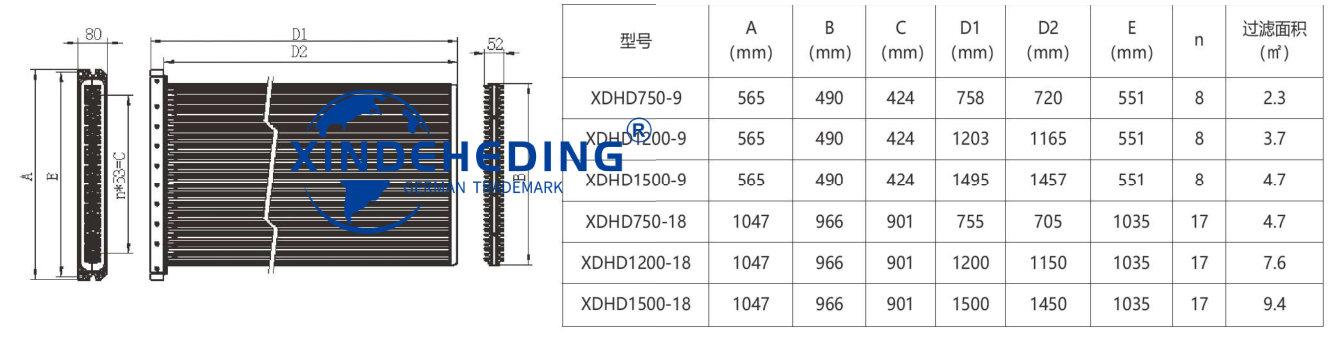

The plicated design of the sinter-plate filter have big filtration area. Our 500*1500mm size filter has 4.75m2.

so the dust collector could design small and that could save lots of space for the company. also, the rigid structure making all the folding area effective.

UHMWPE base material: 30um@4mm thick;

PTFE coating: 2-3um@5um thick.

English

English