Wholesale Professional Design PTFE Coating - Sinter plate filter - HSL type - Plastic Sintered Plate

filter element consists of sintered polyethylene PE. An additional PTFE-coating gets into the pores of the PE-basic body and forms a micro-porous, non-sticking. This combined material is most extensively chemical resistant.

Both the material and the specially developed lamella, changed to the delta-shaped extended-surface pattern make the filter element very stable and rigid, combined with the possibility of an optimum cleaning of the horizontal elements, installed from the side.

Comparing to conventional filter media:

no movement in the filter media

no wear

Product Advantages:

High dust removal accuracy: Micro sized filter holes can remove 100% of dust particles above 1um, and can remove most of the dust particles above 0.1um.

Large filtration area: The corrugated design of the filtration area allows for 3-6 times the filtration area of the filter bag within the same volume.

Strong self-cleaning ability: The rigid structure allows the blowback gas to act more directly on the powder attached to the filter surface, without buffering, resulting in a thorough cleaning effect.

Clearing water and oil: The burning components of the filter element have a deeper performance in clearing water and oil.

Long service life: With high strength and toughness, it can withstand the repeated impact of high-pressure gas thousands of times a day, has super strong acid and alkali resistance, and perfect self-cleaning effect, with a service life of more than 10 years.

Constant pressure: The plastic fired board matrix will not experience blockage.

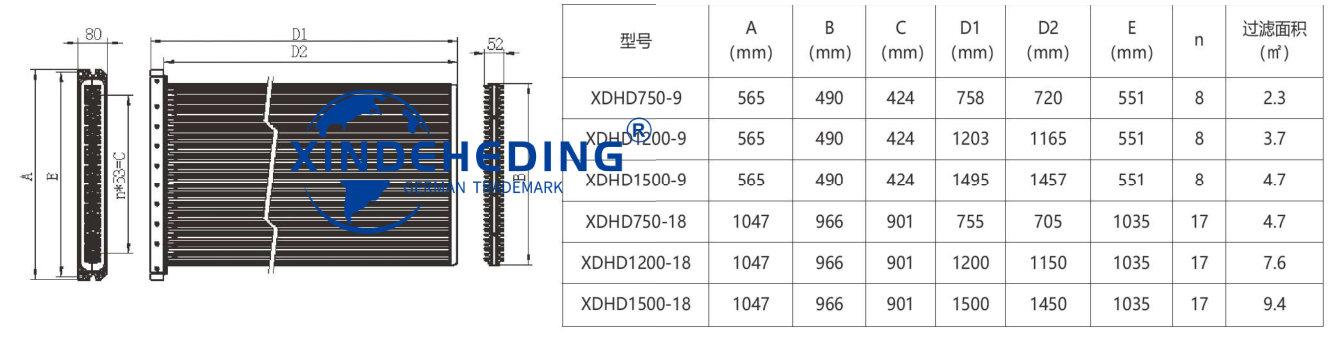

XDHD HSL Plate Filter Elements

| Steel Industry | Nonferrous Metallurgy | Automobile Industry | Ore Processing | Rubber Tyre Industry |

| Electronics Industry | Foundry | Laser-Cutting | Chemical Industry | Pharmacy |

| Food Processing | Glass and Ceramics Industry | Cement and Lime Industry | Metal Work | … |

English

English