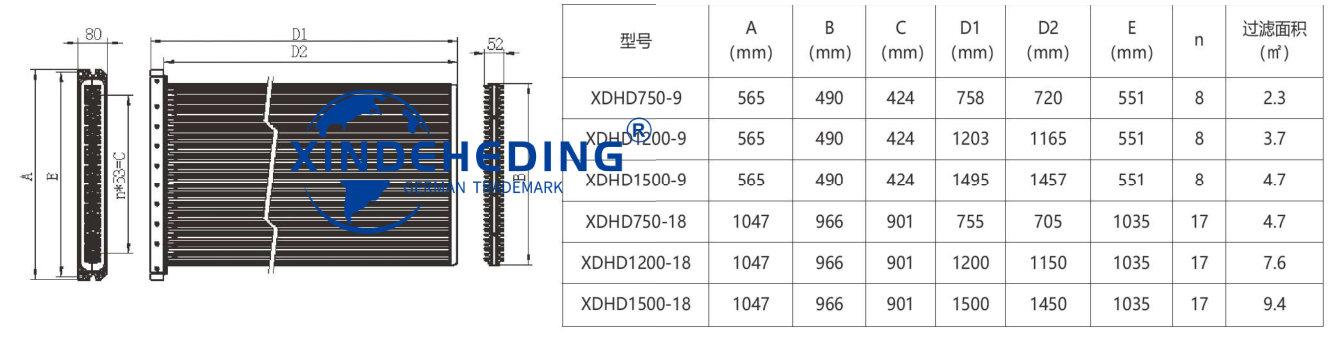

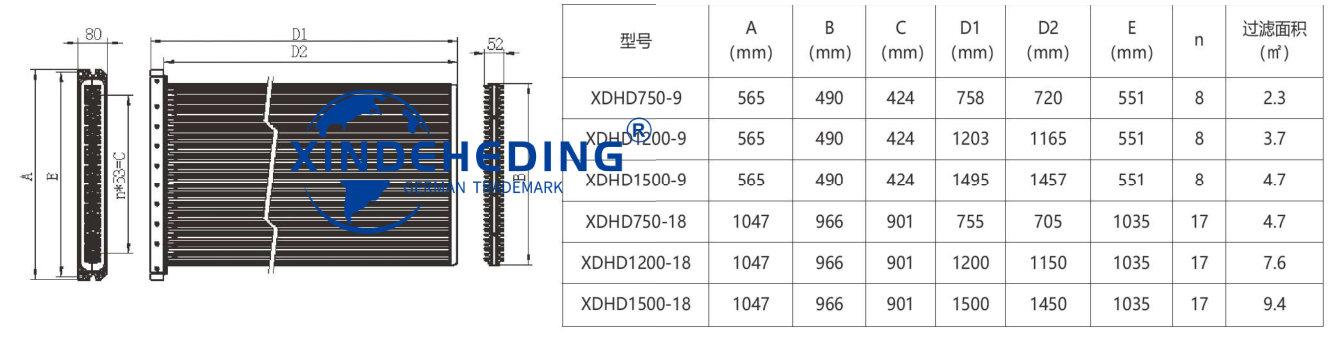

Model HSL 70°C / 158°F ,Sinter Plate Filter,HSL Sinter Plated Filter, Type HSL 1500/18, HSL1500 18, Sinter Plate Tech

The base body of the XDHD sinter-plate filter, which was developed in-house and is protected by patents world-wide, is made of sintered polyethylene (PE). Deposition of the product on the surface - classical surface filtration - is achieved by means of a coating which can vary in composition and type. In all cases the coating is embedded in the pores of the PE base body and forms a microporous surface.

The coating is comprised as standard ofPTFEand, in conjunction with the base body material (PE), guarantees extensive resistance to chemicals

For elements marked withP(erformance), the composition of the coating was developed further: The PTFE fraction was reduced and replaced by PE, resulting in an even more uniform surface and ultimately less pressure loss at the element

On the elements marked withH(alogen-free), all halogens were removed from the coating. This is a requirement imposed by the tobacco industry for example.

Elements marked withM(ineral) have a coating consisting of mineral components, which makes them resistant over the ph range from 1 to 12 and also to numerous coolants and their additives

All elements are available in addition in a non-charging version, and the antistatic elements also come with a certificate.

Very low clean gas values < 0.1 mg/m³ (depending on the dust) result in a high rate of product recovery and protect man, machine and the environment from dust

A very long service life, also where abrasive media are involved, reduce the costs for servicing and spare parts

Constant operating conditions (pressure and suction ratios) ensure stable processes with less control effort

The materials used and the special geometry combine to lend the XDHD sinter-plate filter unique properties, e.g. the elements can be washed and recycled and the base body can be recoated - dependent on the dust. In-house production of the filter mediumandplant enables optimum coordination of the deposition of product with the particular process.

XDHD HSL Plate Filter Elements

| Steel Industry | Nonferrous Metallurgy | Automobile Industry | Ore Processing | Rubber Tyre Industry |

| Electronics Industry | Foundry | Laser-Cutting | Chemical Industry | Pharmacy |

| Food Processing | Glass and Ceramics Industry | Cement and Lime Industry | Metal Work | … |

English

English